With the PBA 320–400 TPH Stationary Asphalt Plant from Polygonmach you can experience the Ultimate in Efficient Asphalt Production

The pinnacle of productivity and innovation in asphalt manufacturing can be found in Polygonmachs PBA 320–400 TPH Stationary Asphalt Plant. Large-scale construction projects are the target market for this cutting-edge machinery which streamlines operations and maximizes the entire production process to deliver superior results. This page examines PBA 320-400 TPH Stationary Asphalt Plants key features assembly process specifications and unique selling points. One type of high-capacity equipment used to create high-quality asphalt for large construction projects is the PBA 320–400 TPH Stationary Asphalt Plant. The robust requirements of major infrastructure projects like highways airports and industrial sites are what this plant is designed to withstand. It can generate between 320 and 400 tons of asphalt per hour. Even the most ambitious projects will be successfully and on schedule thanks to the projects high production capacity. The objectives of this plants design are outstanding quality and consistent performance. Because of the precise control over the production process that the advanced technology used in its construction provides the asphalt meets the highest industry standards. Because of its accuracy the asphalt works well in a variety of environmental conditions and is appropriate for a broad range of construction applications. It is also long-lasting.

The Benefits and Functionality

Large-scale projects benefit greatly from the PBA 320-400 TPH Stationary Asphalt Plants many features. Its remarkable production capacity is one of its most prominent benefits. Its 400 tons per hour production capacity means that this plant can handle large-scale projects and deliver and finish them on schedule. In addition to meeting the high demands of significant construction projects this high output capacity aids in maintaining project timelines. High-quality asphalt is also emphasized in the design of the plant. The sophisticated control systems guarantee that each batch of asphalt fulfills exacting quality requirements producing a durable and dependable final product. Furthermore the plant was designed with energy efficiency in mind which lowers operating costs and promotes ecologically friendly building methods. This emphasis on sustainability and efficiency fits in well with current business trends and has a positive cost and environmental impact.

Durability and Energy Efficiency

The PBA 320-400 TPH Stationary Asphalt Plants energy efficiency is one of its main features. Its sophisticated technology is designed to maximize production output while consuming the least amount of energy possible. By doing this the plants contribution to sustainable building methods is reinforced and operational costs are decreased. The plant minimizes its environmental impact and reduces greenhouse gas emissions by optimizing its energy use. Another noteworthy quality of the plant is its resilience. It is built to endure the rigors of continuous operation using sturdy high-quality materials. Because of its durability the plant requires fewer maintenance and repairs over time which lowers overall costs and lengthens its operational life. The plants strength and dependability guarantee that even in the most trying circumstances it will be a valued asset for the duration of its service life.

Personalized Setups and Outstanding Assistance

One of the main benefits of the PBA 320-400 TPH Stationary Asphalt Plant is its flexibility. It can be tailored to fit the unique needs of various projects enabling configuration changes to maximize effectiveness and productivity. Because of its versatility it can be used to meet a variety of construction needs and provide specialized solutions that improve project outcomes. Outstanding after-sale support is another attribute of Polygonmach. To guarantee that the plant runs efficiently for the duration of its life the company provides comprehensive maintenance services help with troubleshooting and access to spare parts. Comprehensive training is part of this support giving plant operators the abilities and know-how needed to optimize the plants performance. Because of Polygonmachs dedication to customer service the plant will continue to run smoothly and dependably giving customers peace of mind.

Assembly and Components

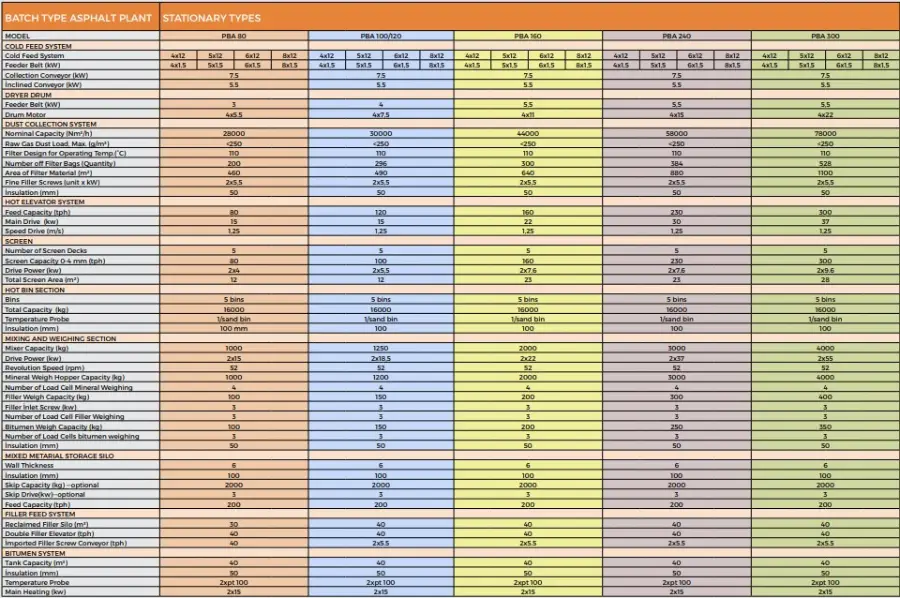

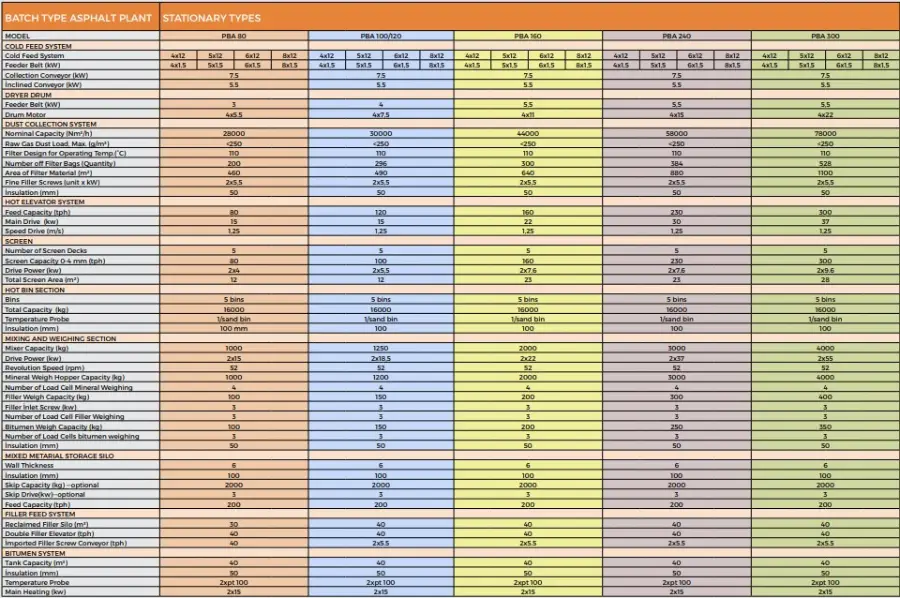

A number of vital parts combine to form the PBA 320-400 TPH Stationary Asphalt Plant which produces asphalt of superior quality. When combining heated aggregates and asphalt binder to make the finished product an asphalt mixer is a vital component. The plant can use either batch mixers or drum mixers each with unique benefits in terms of consistency and flexibility depending on the needs of the project. The operation of the plant also depends on bitumen tanks aggregate feeders drying drums filter systems and control systems. Aggregate feeders provide the right amounts of materials and the drying drum makes sure the aggregates are ready for use. Bitumen tanks store and heat the binder while the filter system protects the environment by collecting dust and particulate matter. Ensuring precision and efficacy the control system oversees the complete production process. Establishing the base installing necessary hardware and configuring the control system to guarantee smooth operation are all part of the assembly process for these components.

What Is Different About Polygonmach?

Polygonmach is unique in the industry because it prioritizes ongoing innovation and development. To keep its facilities at the forefront of the sector the company makes significant investments in research to advance the technology used in asphalt production. Because of this dedication to innovation customers can take advantage of the most recent improvements in production quality and efficiency. Another important distinction is Polygonmachs commitment to offering all-encompassing support. To guarantee that customers can efficiently manage and care for their plants the business provides comprehensive training and continuing assistance. This methodology not only optimizes the plants efficiency but also guarantees that customers are adequately equipped to manage any obstacles that may emerge. Polygonmach is a top option for professionals in the industry looking for dependable and superior asphalt production solutions because of its emphasis on both technological advancement and customer support.

You can get a price by filling out the form