With Polygonmachs PBA 240–320 TPH Stationary Asphalt Plant

You can embark on an efficient asphalt production journey into the future. Designed to transform the asphalt production process Polygonmachs PBA 240-320 TPH Stationary Asphalt Plant offers unparalleled quality and efficiency for major construction projects. High-volume asphalt projects benefit greatly from this state-of-the-art equipment because it guarantees optimal performance. We will examine the features parts assembly procedure and special benefits that distinguish the PBA 240-320 TPH Stationary Asphalt Plant from its rivals in this article.

What is the PBA Stationary Asphalt Plant with 240-320 TPH Capability?

This plant which can produce between 240 and 320 tons per hour ensures steady effective operation—a necessary quality for keeping up the pace of big projects. This facility is designed to withstand the rigorous specifications of building projects like building highways airports or industrial complexes. This plant excels at providing superior quality asphalt by carefully regulating the manufacturing process. Each batch produces a product that is dependable and long-lasting meeting strict industry standards. A high degree of precision and quality control is necessary to produce asphalt that can withstand heavy traffic and a variety of weather conditions assuring long-lasting performance and safety.

Benefits and Features

The PBA 240-320 TPH Stationary Asphalt Plants offer numerous advantages that are particularly beneficial for large-scale construction projects. One of its primary advantages is its large production capacity. With the ability to produce 240–320 tons of asphalt per hour even the largest projects can be completed on schedule. For construction projects to stay on schedule and meet deadlines a high output capacity is essential. The superior quality of asphalt produced is another noteworthy advantage. The highest industry standards are met by the asphalt thanks to the plants exact control over the production process. As a result the created infrastructure performs better and lasts longer. The product is also of exceptional quality and durability. The plant is also built with energy efficiency in mind which lowers operating costs and promotes green building techniques.

Longevity and Energy Efficiency

The PBA 240-320 TPH Stationary Asphalt Plant is particularly notable for its energy efficiency. Because of its efficient design and energy-saving operational procedures its an economical and ecologically friendly option. Because of its focus on energy efficiency which aligns with the growing demand for sustainable construction methods the plant is a desirable alternative for modern construction projects. The plants construction was done with high-quality materials which guarantees dependability and longevity. This plants robust design makes it a worthwhile long-term investment by lowering maintenance costs and extending its operational life. The PBA 240-320 TPH Stationary Asphalt Plant is robust enough to endure continuous operation demands ensuring consistent performance and dependability across a range of projects.

Personalized Setups and Outstanding Help

Configurable configurations are one of the most remarkable aspects of the PBA 240-320 TPH Stationary Asphalt Plant. The plant can be modified to meet the needs of a particular project guaranteeing optimal productivity and efficiency. The plants adaptability to different project requirements makes it a valuable and versatile asset for construction teams. Together with first-rate after-sale assistance Polygonmach also provides thorough maintenance troubleshooting and spare part availability. This comprehensive support makes sure that the plant runs efficiently for the duration of its life giving customers peace of mind. The company guarantees that clients are well-equipped to operate the plant effectively and efficiently through comprehensive training and support services demonstrating its commitment to customer satisfaction.

Assembly and Components

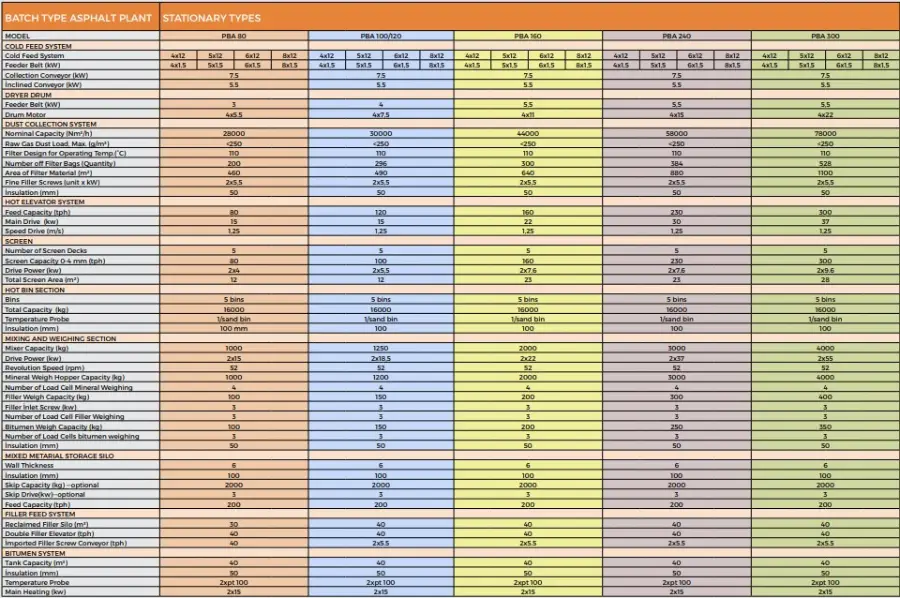

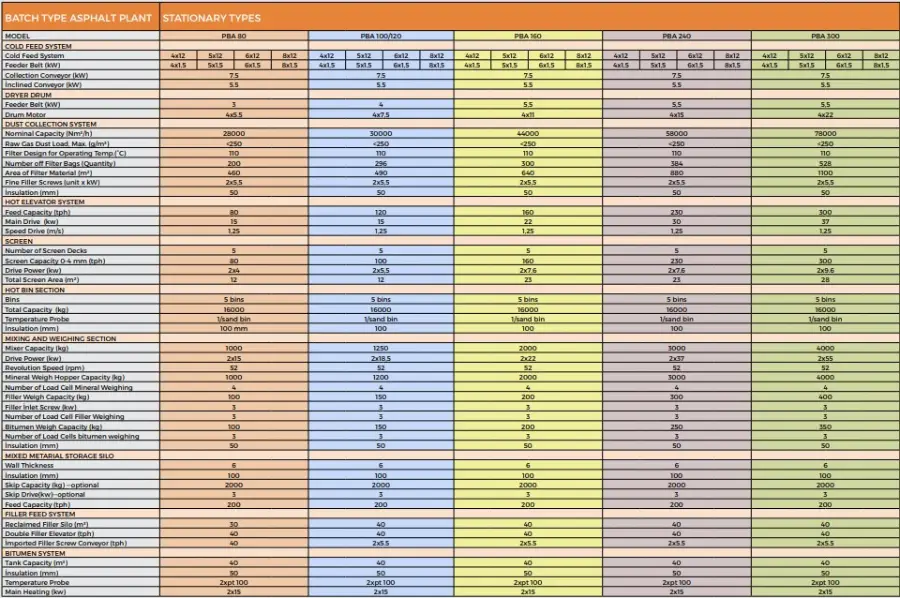

A number of essential parts of the PBA 240-320 TPH Stationary Asphalt Plant come together to form a cohesive unit that produces asphalt of superior quality. The heated aggregates and liquid asphalt binder are mixed in the asphalt mixer also known as the mixing unit to produce the finished product. The plant can use batch mixers or drum mixers each of which has advantages over the other in terms of control and consistency depending on the requirements of the project. The right amounts of various-sized aggregates are supplied into the mixing process thanks to aggregate feeders. These feeders preserve the asphalt mixs uniformity and quality under the direction of the plants central system. The aggregates are effectively bonded to the asphalt binder by the drying drums removal of moisture and application of the necessary heat. By capturing dust and other particulate matter the filter system safeguards the environment and guarantees adherence to air quality standards.

The Control System and Bitumen Tanks

Specialized storage containers called bitumen tanks are made to heat and maintain the asphalt binder at a temperature that is suitable for work. In order to keep the bitumen liquid and provide precise and effective mixing with the aggregates these insulated tanks are fitted with heating elements. The control system which functions as the plants brain supervises and plans every step of the production process guaranteeing accurate mixing and measurement as well as general flow management. The base and structural supports aggregate feeders drying drum bitumen tanks filter system and control system configuration are all part of assembling the PBA 240-320 TPH Stationary Asphalt Plant. The plant is prepared to produce high-quality asphalt effectively and dependably thanks to this meticulous and methodical assembly process.

What Makes Polygonmach Unique?

Putting a lot of effort into cutting-edge research and development to continuously advance asphalt production technology sets Polygonmach apart from rivals. Because of their dedication to innovation their plants are consistently at the forefront of industry standards. Additionally Polygonmach offers thorough training and support to make sure clients are prepared to handle the PBA 240-320 TPH Stationary Asphalt Plant efficiently. This support ensures smooth operations for the duration of the plants life and includes maintenance troubleshooting and the provision of spare parts. Leaders in the industry also favor Polygonmach because of its commitment to affordability and sustainability. In line with the rising demand for sustainable building solutions the companys plants are built to maximize productivity and quality while minimizing environmental impact. Clients who choose Polygonmach are investing in a time when every construction project will seamlessly incorporate sustainability efficiency and quality.

You can get a price by filling out the form