Use Polygonmachs PBA 140-160 TPH Stationary Asphalt Plant to explore the world of productive asphalt production

For large-scale construction projects Polygonmachs PBA 140-160 TPH Stationary Asphalt Plant is an innovative way to change the asphalt production process. Modern machinery like this one guarantees quality and efficiency in each batch of asphalt produced while adhering to the stringent specifications of contemporary building. This post will cover the general assembly procedure internal workings of the PBA 140-160 TPH Stationary Asphalt Plants and unique features that make it stand out from competing products.

Which 140–160 TPH Stationary Asphalt Plant does PBA manufacture?

This cutting-edge high-capacity PBA 140–160 TPH Stationary Asphalt Plant produces premium asphalt for large construction projects. This plants 140–160 tons per hour production capacity guarantees dependable and effective operation. guaranteeing a steady supply of excellent asphalt that because it is made to exact specifications for large-scale projects expedites the construction process. With exact control over the production process this plant guarantees that the asphalt produced satisfies industry standards. Roads highways and commercial complexes can be constructed with the help of the PBA 140-160 TPH Stationary Asphalt Plant which consistently produces high-quality asphalt. Its creative design and effective operation make it a priceless addition to any significant construction project.

Benefits as well as Usefulness

Because of its many features the PBA 140-160 TPH Stationary Asphalt Plant is perfect for large-scale construction projects. Its extraordinary production capacity is by far its greatest advantage. Construction teams can fulfill deadlines without sacrificing quality because the plant can produce 140–160 tons of asphalt per hour. To complete big projects on schedule and under budget a high output level is required. The plants remarkable asphalt production is an additional important advantage. To guarantee that the asphalt satisfies the highest industry standards the PBA 140-160 TPH Stationary Asphalt Plant provides exact control over every step of the production process. This degree of control prolongs the life and improves the functionality of built roads and structures in addition to producing incredibly robust and durable asphalt.

Sturdiness and Energy Conservation

Efficiency in energy use was considered during the design of the PBA 140-160 TPH Stationary Asphalt Plant. It is an economical and environmentally responsible option for construction projects because of its energy-efficient operating procedures. This emphasis on energy efficiency contributes to a greener future by reducing operating costs and meeting the growing demand for sustainable construction methods. Determination and toughness are important attributes of this plant. The PBA 140-160 TPH Stationary Asphalt Plant is made to last the demands of continuous operation using high-quality materials. Given its robustness the plant will save costs by requiring fewer maintenance visits over time. Because of their extended operational life plants can support a wide range of projects and offer a great return on investment.

Configurations that are customizable and extensive support

The PBA 140-160 TPH Stationary Asphalt Plants configurable features are one of its standout qualities. The plants operational efficiency and productivity can be optimized by customizing it to suit the unique requirements of various projects. Because of its adaptability construction teams can use the plant to fit different project requirements which makes it a useful tool for a range of construction scenarios. In addition Polygonmach offers comprehensive post-purchase assistance encompassing upkeep diagnostics and the procurement of replacement components. Throughout its life the plant will function without hiccups thanks to this extensive support. The companys dedication to providing comprehensive training and support services which guarantee clients are well-equipped to operate the plant efficiently and effectively is evident in its commitment to customer satisfaction.

Assembly and Components

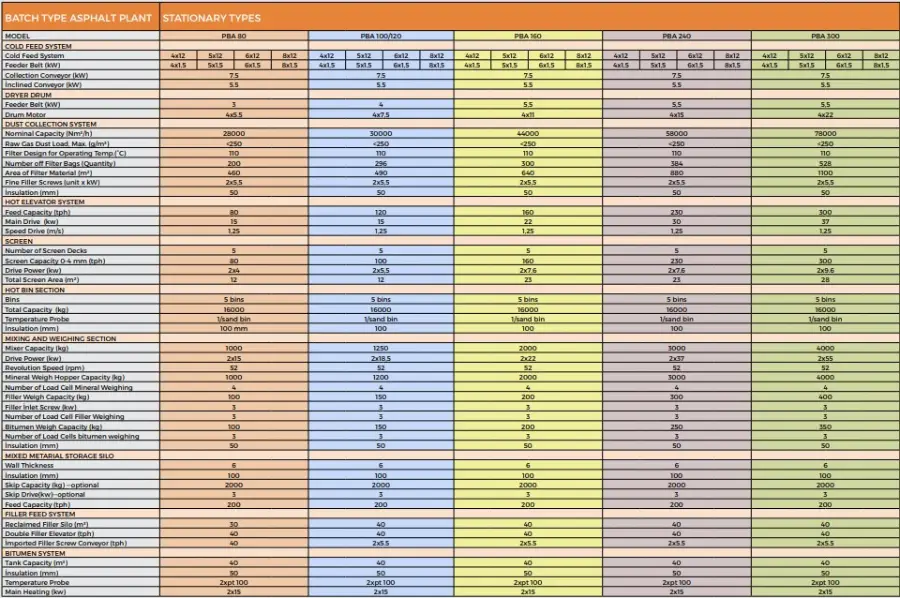

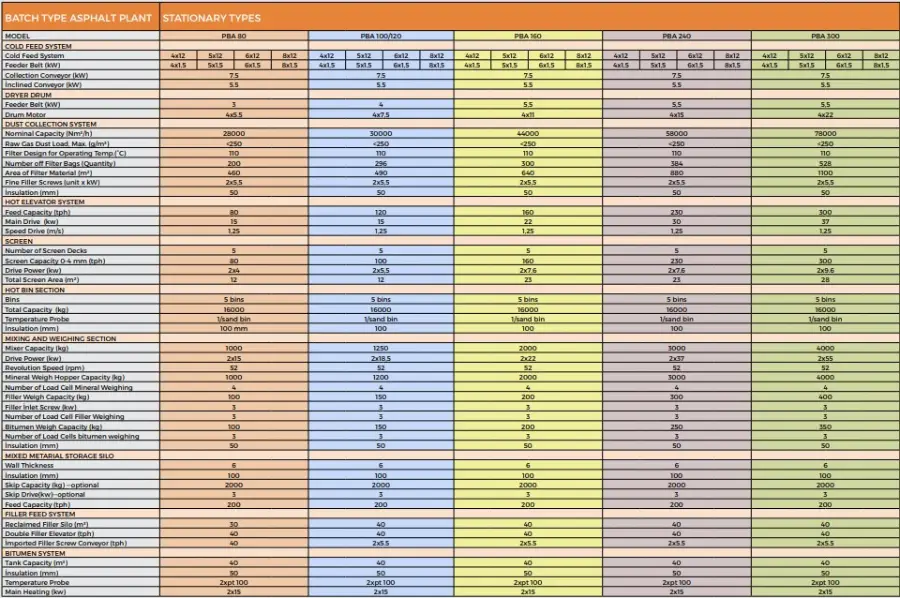

A number of essential parts of the PBA 140-160 TPH Stationary Asphalt Plant combine to provide asphalt of the highest caliber. The final asphalt mixture is made by mixing heated aggregates and liquid asphalt binder in an asphalt mixer also known as a mixing unit. To guarantee the uniformity and caliber of the asphalt product this procedure is carried out under carefully monitored circumstances. The plant can use batch mixers or drum mixers depending on the particular requirements and preferred methods of operation of the project. The right amounts of varying-sized aggregates are fed into the mixing process by aggregate feeders. The precise aggregate proportions ensured by these feeders which are managed by the plants central control system preserve the asphalt mixs quality and uniformity. In order to prepare the aggregates and get them to the necessary temperature a drying drum is necessary. By capturing and eliminating dust and other particulates the filter system protects the environment and complies with air quality standards.

Bitumen Storage Tanks and Management System

In order to keep the asphalt binder at a temperature that is suitable for mixing bitumen tanks are special storage containers. The bitumen is kept liquid in these insulated tanks by heating elements which allows for precise and effective mixing with the heated aggregates. The entire production process is managed and coordinated by the control system which is the plants brain. With the help of this sophisticated computerized system production flow is managed overall heating and drying processes are precisely controlled and mixing and measurement are done precisely. Installation of the aggregate feeders and drying drum addition of the bitumen tanks and filter system base and structural support setup and control system configuration are all steps in the assembly process of the PBA 140-160 TPH Stationary Asphalt Plant. This meticulous and methodical assembly procedure guarantees that the plant is prepared to supply high-quality asphalt effectively and consistently.

What Is Unique About Polygonmach?

Polygonmach sets itself apart from rivals by emphasizing cutting-edge research and development and consistently coming up with new ideas to advance the technology used in asphalt production. Their plants are constantly at the forefront of industry standards thanks to their dedication to innovation. To ensure that clients are adequately prepared to operate the PBA 140-160 TPH Stationary Asphalt Plant effectively and efficiently Polygonmach also offers thorough training and support. Ensuring smooth operations for the duration of the plants lifespan this support includes maintenance troubleshooting and the provision of spare parts. Furthermore leaders in the industry choose Polygonmach because of its commitment to cost-effectiveness and sustainability. As the market for sustainable building solutions continues to grow the companys plants are built to minimize their negative effects on the environment while maximizing quality and productivity. Clients who select Polygonmach are investing in a future where sustainability efficiency and quality are incorporated into every construction project with ease.

You can get a price by filling out the form