With Polygonmachs PBA 100-120 TPH Stationary Asphalt Plant Explore the Future of Efficient Asphalt Production

The Polygonmach PBA 100-120 TPH Stationary Asphalt Plant has the power to completely change how asphalt is produced for large-scale building initiatives. This state-of-the-art equipment is an essential part of large-scale construction projects because it is made to maximize and streamline asphalt production. This post covers the intricate internal workings parts assembly process and special features that distinguish the PBA 100-120 TPH Stationary Asphalt Plants from rivals in great detail.

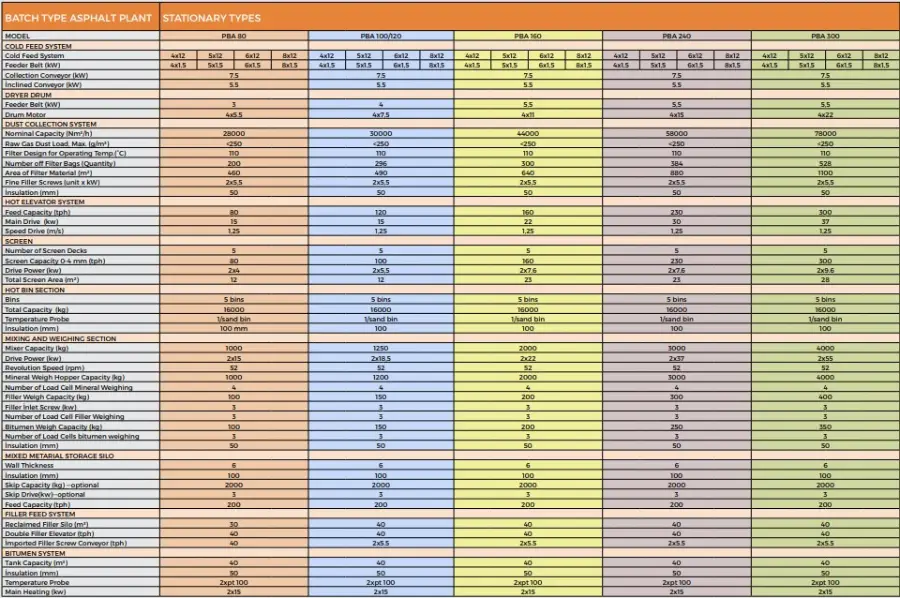

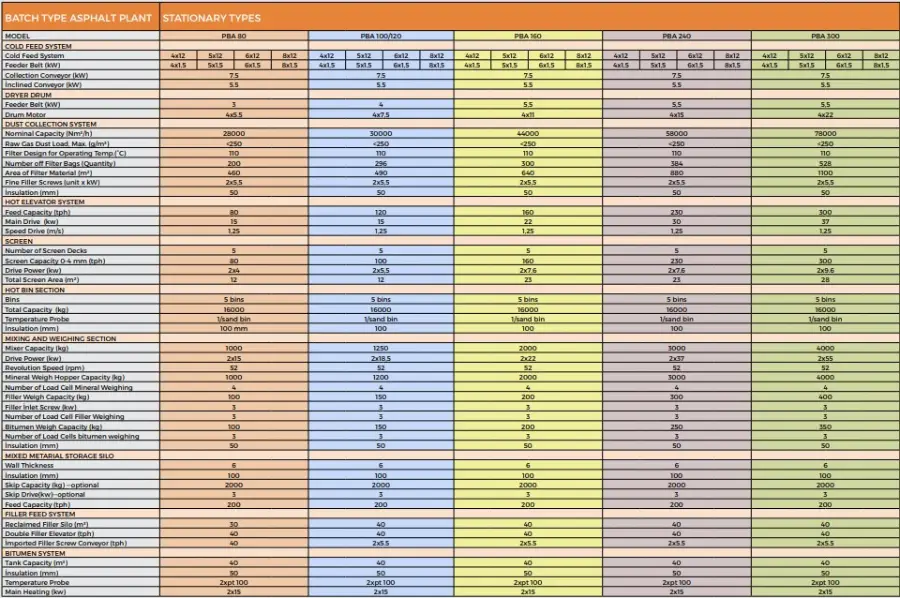

What goes into building a PBA 100-120 TPH Stationary Asphalt Plant?

Large-scale construction projects require an asphalt production plant with a high capacity and the PBA 100-120 TPH Stationary Asphalt Plant is designed to meet those needs.

This facility guarantees dependable high-efficiency operation with a production capacity of 100–120 tons of asphalt per hour. Because of its painstaking attention to detail every batch of asphalt is guaranteed to meet the highest industry standards ensuring the durability and functionality of the built roads and structures. This plant is designed to function extraordinarily well whether it is used on commercial structures or highways.

Features and Benefits

The plants outstanding asphalt quality is yet another significant benefit. High-quality asphalt that complies with strict industry standards is produced by the PBA 100-120 TPH Stationary Asphalt Plant which guarantees exact control over the production process. For the long run this consistency in quality benefits both builders and users by improving the final pavements performance and durability. Both durability and energy efficiency. The PBA 100-120 TPH Stationary Asphalt Plant is an energy-efficient machine. It is an affordable and environmentally friendly option for building projects because its design and operating procedures are optimized to reduce energy consumption. Because of its durability the plant can operate for a longer period of time with lower maintenance costs offering a dependable option for continuous asphalt production.

Configurations that can be Customized along with Extensive Support

Customizable configurations are one of the PBA 100-120 TPH Stationary Asphalt Plants best features. To ensure optimal productivity and efficiency the plant can be customized to match the requirements of individual projects. Building teams can modify the plant to meet different project needs thanks to its adaptability which makes it a useful tool. In-depth post-purchase assistance is also provided by Polygonmach including upkeep troubleshooting and the availability of spare parts. The plant will run faultlessly for the duration of its life thanks to this thorough support. Extensive training and support services are offered to clients to ensure they are well-equipped to operate the plant efficiently demonstrating the companys commitment to customer satisfaction.

Assembly and Components

To guarantee the uniformity and caliber of the asphalt product this procedure is carried out under carefully monitored circumstances. Providing the appropriate amount of various-sized aggregates to the mixing process is the responsibility of the aggregate feeder. The exact aggregate proportions are ensured by these feeders which are managed by the plants central control system upholding the asphalt mixs consistency and quality. Dust and other particulate matter are captured and eliminated by the filter system which ensures environmental protection while the drying drum dries out the aggregates and raises their temperature to the necessary level.

The Control System and Bitumen Tanks

In order to heat and maintain the asphalt binder at a temperature that is suitable for mixing bitumen tanks are special storage containers. By keeping the bitumen liquid and equipped with heating elements these insulated tanks allow for precise and effective mixing with the heated aggregates. The brains behind the plant the control system ensure accurate measurement and mixing control over the heating and drying processes and overall flow management of the production process.

What Differentiates Polygonmach?

There are various reasons why Polygonmach is unique in the market. First and foremost the business prioritizes cutting-edge research and development constantly coming up with new ideas to advance the technology used in asphalt production. Their plants always lead the industry in standards thanks to their dedication to innovation. In order to ensure that clients can operate the PBA 100-120 TPH Stationary Asphalt Plant effectively and efficiently Polygonmach also offers thorough training and support. This support ensures smooth operations for the duration of the plants life and includes maintenance troubleshooting and spare part availability. Finally industry leaders choose Polygonmach because of its commitment to cost-effectiveness and sustainability. In line with the rising demand for sustainable building solutions the companys plants are built to maximize productivity and quality while minimizing environmental impact. When clients choose Polygonmach they are making an investment in a time when every construction project will seamlessly incorporate sustainability efficiency and quality.

You can get a price by filling out the form