The Polygonmach PBA 40-60 Tph Stationary Asphalt Plant is Your Gateway to Productive Asphalt Production

The PBA 40–60 Tph Stationary Asphalt Plant by Polygonmach is a state-of-the-art option made to maximize the production of asphalt for a variety of building projects. This cutting-edge machinery guarantees reliable and effective performance making it an invaluable resource for any major construction project. This post will explore the PBA 40–60 Tph Stationary Asphalt Plant including its definition workings major parts assembly procedure and unique selling points.

What is the 40–60 Tph Stationary Asphalt Plant manufactured by PBA?

The PBA 40–60 Tph Stationary Asphalt Plant is a stationary high-capacity facility designed to generate premium asphalt. This plant is made to handle the demands of large-scale construction projects because it can produce 40 to 60 tons of asphalt per hour. For projects requiring a steady supply of asphalt its stationary design guarantees steady and continuous production which is essential. The PBA 40–60 Tph Stationary Asphalt Plants energy-efficient design lowers energy consumption and operating costs while upholding high standards of quality providing benefits to the environment as well as the economy.

Benefits and Usability

Project completion on schedule and within budget is ensured by the capacity to produce large volumes of asphalt quickly and efficiently. An additional noteworthy benefit is the outstanding caliber of asphalt generated. The asphalt is guaranteed to meet strict industry standards thanks to the plants exact control over the production process. The resilience and lifespan of roads and other infrastructure depend heavily on this premium asphalt. Furthermore compared to conventional asphalt plants the plants design minimizes energy consumption making it a more cost-effective and environmentally friendly choice.

Assembly and Components

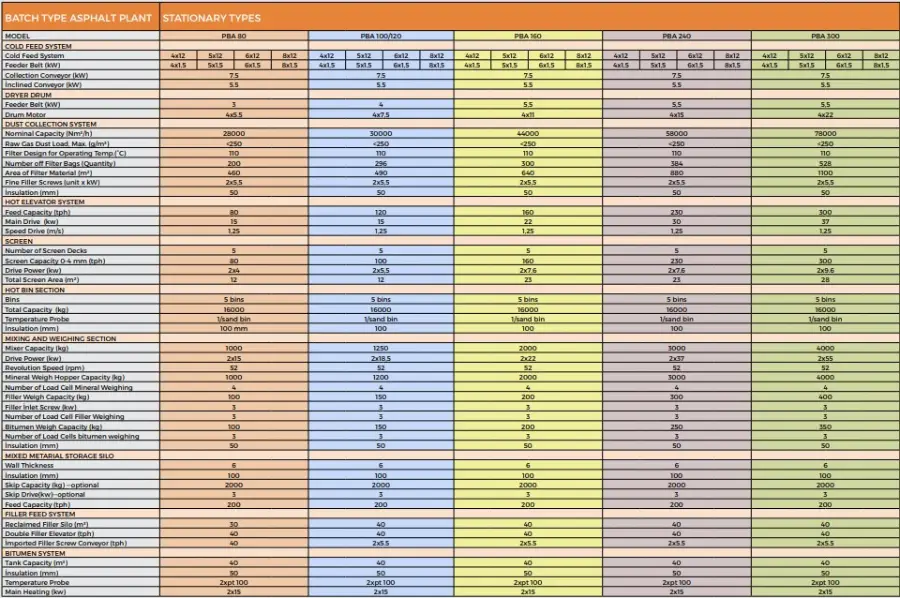

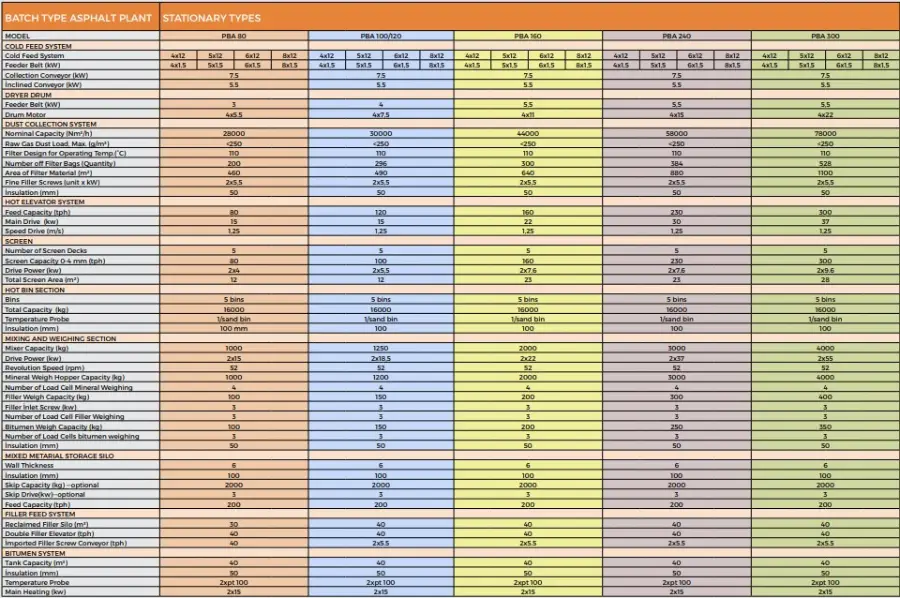

To produce high-quality asphalt the PBA 40–60 Tph Stationary Asphalt Plant is made up of a few crucial parts that operate in unison. The final asphalt mixture is made by mixing the liquid asphalt binder with the heated aggregates in an asphalt mixer also known as a mixing unit. For the mixture to be homogenous and fulfill the required specifications this process is closely supervised. The plant has two options for mixing depending on the needs of the project: drum mixers which produce a consistent product at higher production rates or batch mixers which offer precise control and flexibility. Providing the appropriate amount of various-sized aggregates to the mixing process is the responsibility of the aggregate feeder. The precise proportioning of aggregate is ensured by these feeders which are managed by the central control system of the plant. This helps to preserve the asphalt mixs quality and uniformity. Another essential part is the drying drum which dries out the aggregates and raises their temperature to the necessary level. For the finished product to be strong and long-lasting this guarantees the best possible bonding with the asphalt binder.

Bitumen Tanks and Filtration Systems

By collecting and eliminating dust and other particulate matter produced during the drying and mixing of aggregate the filter system in the PBA 40–60 Tph Stationary Asphalt Plant is essential to environmental protection. Prior to the exhaust air being released into the atmosphere this system usually consists of cyclones or baghouse filters that collect particles. The filtration system guarantees that the plant complies with air quality regulations and contributes to environmental protection by meeting environmental standards. The effective functioning and long-term viability of the filter system depend on routine maintenance and observation. When bitumen is needed for mixing with aggregates bitumen tanks are specialized storage containers made to heat and retain bitumen at a workable temperature. The heating elements in these insulated tanks keep the bitumen liquid which makes it easier to mix precisely and effectively with the heated aggregates. Assuring a steady supply of binder for continuous asphalt production the capacity and number of bitumen tanks can be adjusted based on the size of the asphalt plant and the production requirements.

Assembly and Control System

The PBA 40–60 Tph Stationary Asphalt Plants control system is its brain supervising and directing the whole production process. This state-of-the-art computer-based system guarantees accurate measurement and mixing of the aggregates and asphalt binder as well as control over the drying and heating processes and overall production flow management. Plant managers can ensure the production of high-quality asphalt by using the control systems user-friendly interfaces to monitor operations in real-time and adjust parameters as needed. The flexibility productivity and efficiency of the asphalt plant are all highly impacted by the control systems sophistication. After the base and structural supports are put in place the aggregate feeders and drying drum are installed as part of the plant assembly process. The bitumen tanks and filtration system are then installed. Ultimately the control system is set up to make it easier for the plant to run smoothly. This thorough assembly procedure guarantees that every part is integrated and installed correctly enabling the plant to run smoothly and generate high-grade asphalt.

What Makes Polygonmach Unique?

There are multiple reasons why Polygonmach distinguishes itself from its rivals. First and foremost the business prioritizes cutting-edge research and development consistently pushing the limits of asphalt production technology. Their dedication to innovation guarantees that their asphalt plants are outfitted with the newest features and functionalities providing exceptional dependability and performance. Furthermore Polygonmach guarantees that its clients have all they need to properly operate the PBA 40–60 Tph Stationary Asphalt Plant by offering extensive training and assistance. Polygonmach is also proud of its dedication to sustainability providing solutions that improve the bottom line of the construction industry while also benefiting the environment. Asphalt plants made by Polygonmach combine cutting-edge pollution control technologies and energy-efficient designs to reduce their environmental effect and increase productivity and savings. Polygonmach is a pioneer in the asphalt production sector offering clients cutting-edge machinery and first-rate assistance thanks to its commitment to sustainability and imagination.

You can get a price by filling out the form