The PBA 200-240 TPH Stationary Asphalt Plant from Polygonmach will help you enter the future of efficient asphalt production

With unparalleled efficiency and quality for massive construction projects Polygonmachs PBA 200-240 TPH Stationary Asphalt Plant is built to transform the asphalt production process. Modern machinery guarantees peak performance which makes it a priceless tool for projects needing large amounts of asphalt. The PBA 200-240 TPH Stationary Asphalt Plant is unique in the industry and we will show you why by delving into its functions parts assembly method and special advantages.

The PBA 200-240 TPH Stationary Asphalt Plant: What is it?

Large-scale construction projects require asphalt of the highest caliber which is why the PBA 200-240 TPH Stationary Asphalt Plant has a high capacity. This plant which can produce between 200 and 240 tons per hour guarantees dependable efficient operation which is essential for maintaining the momentum of large-scale projects. This plant is built to withstand the rigorous requirements of construction projects be it highways airports or sizable industrial complexes. By carefully regulating the production process this plant excels in producing asphalt with exceptional quality. The PBA 200-240 TPH Stationary Asphalt Plant produces a product that is dependable and long-lasting by making sure that every batch satisfies stringent industry standards. In order to produce asphalt that can endure the rigors of heavy traffic and variable weather conditions assuring long-lasting performance and safety a high degree of precision and quality control is imperative.

Features and Benefits

Large-scale construction projects benefit greatly from the PBA 200-240 TPH Stationary Asphalt Plants many features. An additional noteworthy benefit is the exceptional caliber of asphalt generated. The facility offers exact control over the manufacturing process guaranteeing that the asphalt satisfies the most stringent industry requirements. As a result the created infrastructure performs better and lasts longer. The product is also of exceptional quality and durability. The facility was also built with energy efficiency in mind which lowers operating expenses and promotes green building techniques.

Sturdiness and Energy Efficiency

For the PBA 200-240 TPH Stationary Asphalt Plant energy efficiency is a major component. Because of its optimized design and operating procedures the plant is both cost-effective and environmentally friendly. Energy-efficient construction methods are becoming more and more popular in modern development projects because they are an essential component of sustainable construction techniques. Because the plant was built using high-quality materials that ensure dependability and durability it has a longer lifespan. Because of its strong design which will eventually lower maintenance costs and increase its operational life the plant is a wise long-term investment. The PBA 200-240 TPH Stationary Asphalt Plant can handle the demanding conditions of continuous operation and maintain a consistent level of performance for a variety of projects. Tailored Configurations and Superb Support. One of the PBA 200-240 TPH Stationary Asphalt Plants most distinctive features is how it is arranged. Customization of the plant is possible to ensure maximum productivity and efficiency while meeting the specific needs of different projects. The plants versatility makes it a useful and practical asset because it can be tailored to meet the needs of various construction projects. Polygonmach provides comprehensive maintenance troubleshooting spare part availability and excellent after-sale support. Thanks in large part to this support customers can rest easy knowing that the plant will continue to operate profitably throughout its life. The companys commitment to meeting customer needs is demonstrated by the comprehensive training and support services it provides to ensure that customers are ready to operate the plant effectively and efficiently.

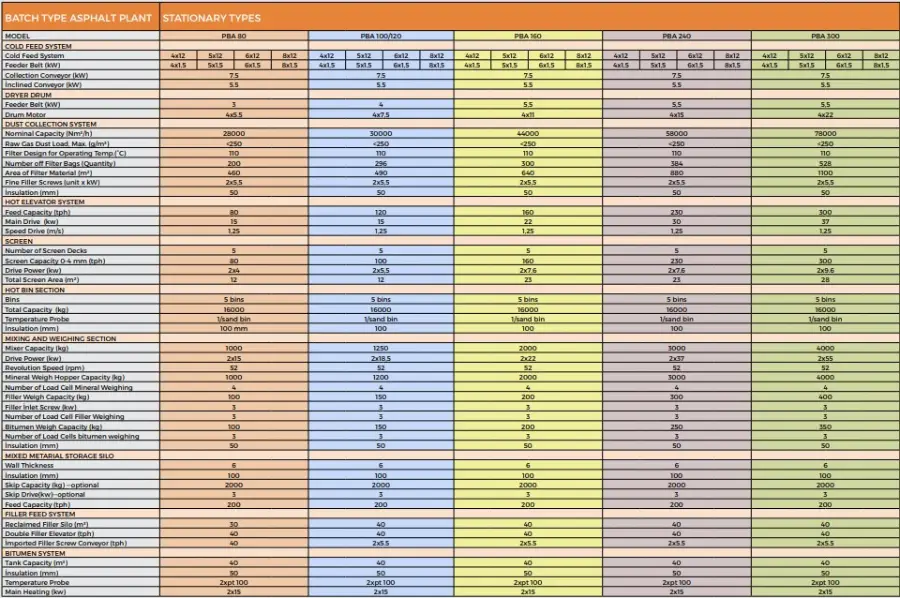

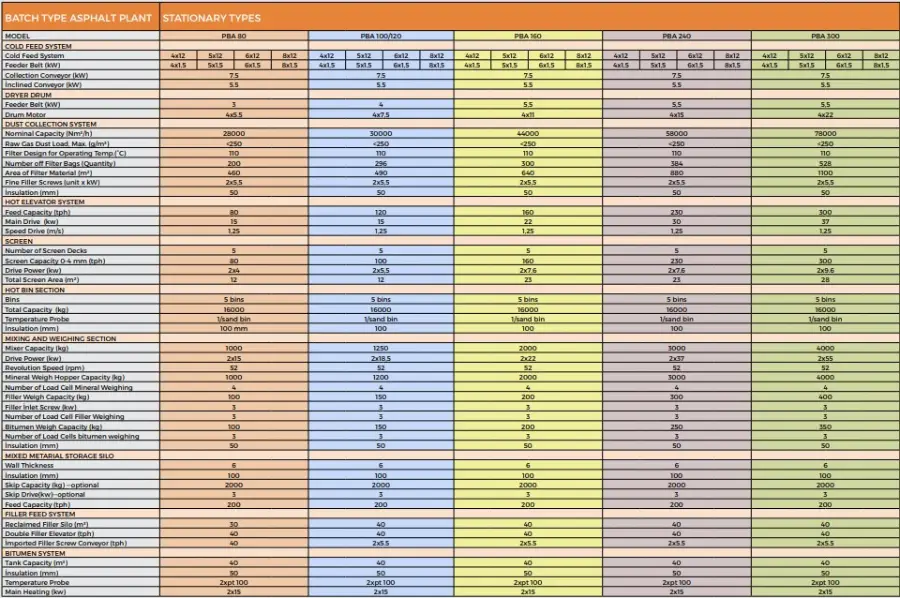

Assembly and Parts

To produce high-quality asphalt the PBA 200-240 TPH Stationary Asphalt Plant is made up of a number of crucial parts that cooperate harmoniously. In order to create the finished product heated aggregates and liquid asphalt binder are combined in an asphalt mixer also known as a mixing unit. Both batch and drum mixers which have different control and consistency benefits can be used by the plant depending on the requirements of the project. Aggregate feeders guarantee that the right amounts of various-sized aggregates are added to the mixture during mixing. These feeders preserve the asphalt mixs uniformity and quality under the direction of the plants central system. The purpose of the drying drum is to eliminate moisture and raise the aggregates temperature to the necessary level so that the asphalt binder and aggregates adhere to one another. The filter system ensures that air quality standards are met while also safeguarding the environment by capturing dust and other particulates.

The control system and bitumen tanks

Specialized storage containers called bitumen tanks are made to heat and maintain the asphalt binder at a temperature that is suitable for work. Since the bitumen is kept liquid in these insulated tanks by heating elements precise and effective mixing with the aggregates is ensured. The control system which functions as the plants brain supervises and plans every step of the production process guaranteeing accurate mixing and measurement as well as general flow management. Installation of the aggregate feeders and drying drum addition of the bitumen tanks and filter system configuration of the control system and base and structural supports are all part of the assembly process of the PBA 200-240 TPH Stationary Asphalt Plant. The plant is prepared to produce high-quality asphalt effectively and dependably thanks to this meticulous and methodical assembly process.

What Makes Polygonmach Unique?

By placing a significant emphasis on cutting-edge research and development and consistently advancing asphalt production technology Polygonmach sets itself apart from rivals. Because of their dedication to innovation their plants are consistently at the forefront of industry standards. In order to guarantee that customers are properly prepared to operate the PBA 200-240 TPH Stationary Asphalt Plant Polygonmach also offers thorough training and support. This support ensures smooth operations for the duration of the plants life and includes maintenance troubleshooting and the provision of spare parts. Industry leaders also favor Polygonmach because of its commitment to cost-effectiveness and sustainability. As the market for sustainable building solutions continues to grow the companys plants are built to minimize their negative effects on the environment while maximizing output and quality. Clients that choose Polygonmach are investing in a time when every construction project will seamlessly incorporate sustainability efficiency and quality.

You can get a price by filling out the form