With Polygonmachs you can produce asphalt with efficiency going forward thanks to its 160–200 TPH Stationary Asphalt Plant

For large-scale construction projects the ground-breaking Polygonmachs 160-200 TPH Stationary Asphalt Plant is expected to revolutionize the asphalt production industry. This post will examine the special qualities and component assembly method of the 160-200 TPH Stationary Asphalt Plants that set them apart from competing goods on the market. The 160–200 TPH Stationary Asphalt Plant maintains exact control over the production process ensuring that every batch of asphalt it produces meets the highest industry standards. Long-lasting high-quality asphalt is produced as a result of this diligence. By utilizing this cutting-edge technology your construction projects will function more efficiently and effectively.

Functionality and Benefits

One of its key benefits is its amazing production capacity. The plant which can produce between 160 and 200 tons per hour ensures that construction teams can comply with quality standards and deadlines. With this high output you can precisely meet deadlines and maintain the projects progress. An additional significant advantage of the plant is the exceptional quality of asphalt it produces. Because of its precise control over the production process asphalt meets the highest industry standards. The end product is therefore of the greatest quality and remarkably durable prolonging the lifespan and usefulness of the constructed roads and structures. Because of its energy-efficient design the plant is a cost-effective and environmentally responsible option for construction projects.

Energy efficiency as well as robustness

Given its emphasis on energy efficiency the plant is a desirable option for modern construction firms aligning with the growing demand for greener construction methods. In addition durability and dependability are crucial to the plants design By purchasing this plant construction companies can boost their return on investment and keep their competitive edge in the market.

Customized Configurations and Comprehensive Support

One of its best features is the configurable options for 160-200 TPH Stationary Asphalt Plants. By tailoring the plant to the specific needs of different projects maximum productivity and efficiency can be guaranteed. Construction teams can use the plant in a range of construction scenarios due to its versatility and ability to adapt to different project requirements making it a valuable asset. Polygonmach provides extensive post-purchase support as well encompassing maintenance troubleshooting and spare part supply. Throughout the plants life this comprehensive support ensures smooth operation. To ensure that clients are adequately prepared to operate the plant effectively and efficiently comprehensive training and support services are offered. This illustrates the businesss dedication to client satisfaction.

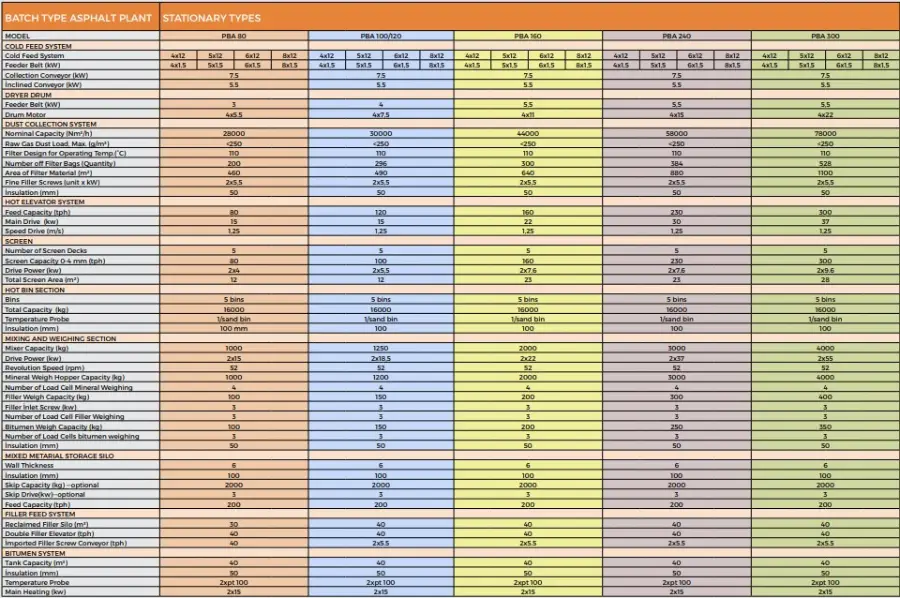

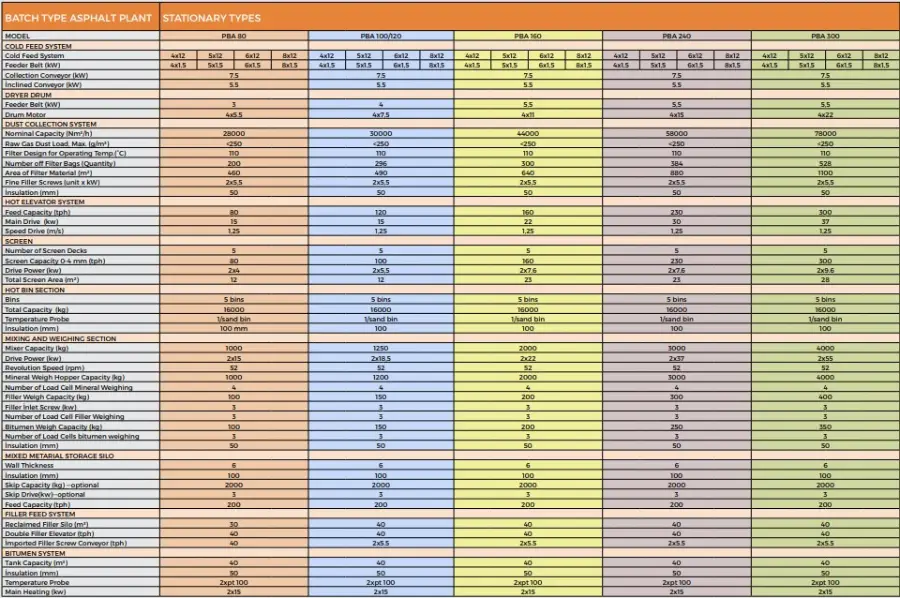

Components and Combination

The 160–200 TPH Stationary Asphalt Plant when combined produces high-grade asphalt thanks to a number of crucial components. Depending on the specific needs and preferred methods of operation of the project the plant may employ batch or drum mixers. Aggregate feeders supply the proper ratios of different-sized aggregates for the mixing procedure. The quality and uniformity of the asphalt mixes are preserved by the exact aggregate proportions that these feeders which are controlled by the plants central control system guarantee. A drying drum is required to prepare the aggregates and bring them to the appropriate temperature. The filter system collects and removes dust and other particulate matter to safeguard the environment and adhere to air quality regulations.

The Bitumen Tanks and Control System

The control system or the brain of the plant oversees and plans the entire production process. This cutting edge computerized system ensures precise measurement and mixing manages the heating and drying procedures and oversees the whole production flow. The assembly process for the 160–200 TPH Stationary Asphalt Plant includes setting up the base and structural supports installing the aggregate feeders and drying drum adding the bitumen tanks and filter system and configuring the control system for efficient and smooth operation. A meticulous and methodical assembly process ensures that this plant is ready to deliver high-quality asphalt reliably and effectively.

What Sets Polygonmach Apart From Rivals

Polygonmach distinguishes itself from competitors by placing a strong focus on state-of-the-art research and development and continuously generating new concepts to advance asphalt production technology. Their commitment to innovation means that their plants are consistently at the forefront of industry standards. To ensure that clients are equipped to operate the 160–200 TPH Stationary Asphalt Plant effectively Polygonmach also provides comprehensive training and support. With the provision of spare parts and maintenance troubleshooting this support will guarantee smooth operations for the duration of the plant. Due to Polygonmachs dedication to sustainability and affordability industry leaders also support the company. Plants owned by the company are designed to minimize their negative environmental effects while maximizing quality and productivity in response to the growing market for sustainable building solutions. By choosing Polygonmach clients are investing in a building project that skillfully combines efficiency quality sustainability and the future.

You can get a price by filling out the form