With the Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant discover the world of efficient asphalt production

Because of Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant asphalt produced for large-scale construction projects will be produced differently. These cutting-edge instruments can optimize the asphalt production process which makes them an invaluable asset for large-scale construction projects. The PBA 120–140 TPH Stationary Asphalt Plant is covered in great detail in this article along with information on its assembly process and special features.

What is the PBA 120-140 TPH Stationary Asphalt Plant like?

We guarantee its dependable and effective operation. Because exact control is maintained throughout the entire production process every batch of asphalt produced by this plant is guaranteed to meet the highest industry standards. The PBA 120-140 TPH Stationary Asphalt Plant is perfect for highways and commercial buildings because it ensures the longevity and functionality of the built roads and structures. It offers better asphalt boosting the stability and longevity of infrastructure projects. The functionalities and advantages.

PBA 120-140 TPH Stationary Asphalt Plants have numerous benefits that are especially beneficial for large construction projects. One of its primary benefits is its remarkable capacity for production. Building teams are able to meet deadlines and work on large-scale projects with efficiency thanks to this high output. The plants extremely high-quality asphalt output is another significant benefit. PBA 120-140 TPH Stationary Asphalt Plant: This plant produces asphalt that satisfies industry standards and is of superior quality because it allows for exact control over the production process. Long-term advantages for both builders and users are ensured by this consistency in quality which also guarantees the final pavements performance and durability.

Longevity and Energy Efficiency

In addition to lowering operating expenses this emphasis on energy efficiency supports the expanding need for sustainable building techniques which will help create a more environmentally friendly future. Another important aspect of this plant is its dependability and durability. The PBA 120–140 TPH Stationary Asphalt Plant is made to last years of continuous use and is composed of premium materials. This robustness guarantees the plant stays operational for a longer period of time and lowers maintenance costs offering a dependable solution for continuous asphalt production. Because of its long lifespan the plant can serve several projects and provides a great return on investment.

Configurations that are customizable and extensive support

The PBA 120-140 TPH Stationary Asphalt Plants adaptable configurations are one of its best qualities. The plant can be modified to meet the unique requirements of a project guaranteeing optimal output and effectiveness. Because of its adaptability construction teams can use the plant to fit different project requirements which makes it a useful tool for a range of construction scenarios. In-depth post-purchase assistance from Polygonmach also includes maintenance troubleshooting and the availability of spare parts. This all-encompassing support guarantees the plants smooth operation for the duration of its life. The companys dedication to providing comprehensive training and support services which guarantee clients are well-equipped to operate the plant efficiently and effectively is evident in its dedication to customer satisfaction.

Establishment and Parts

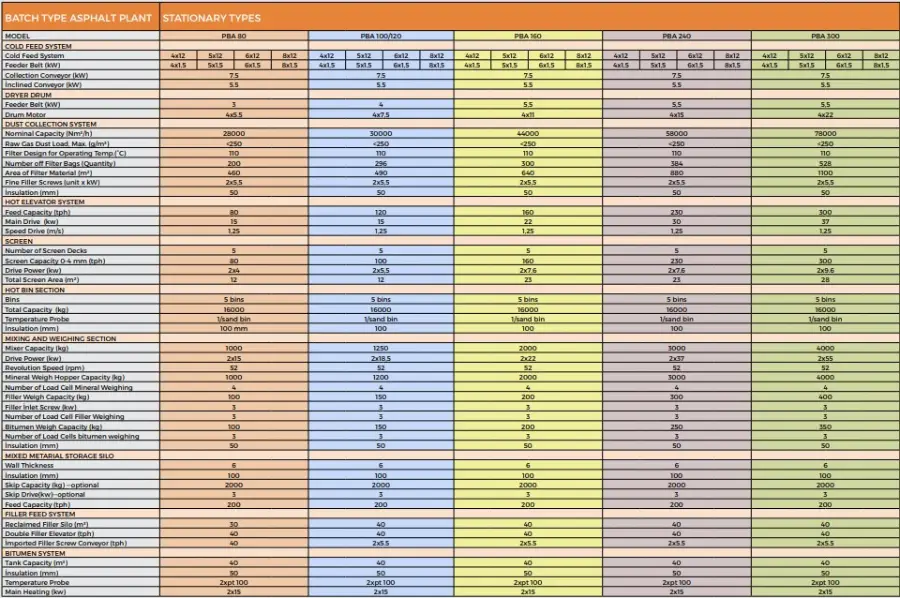

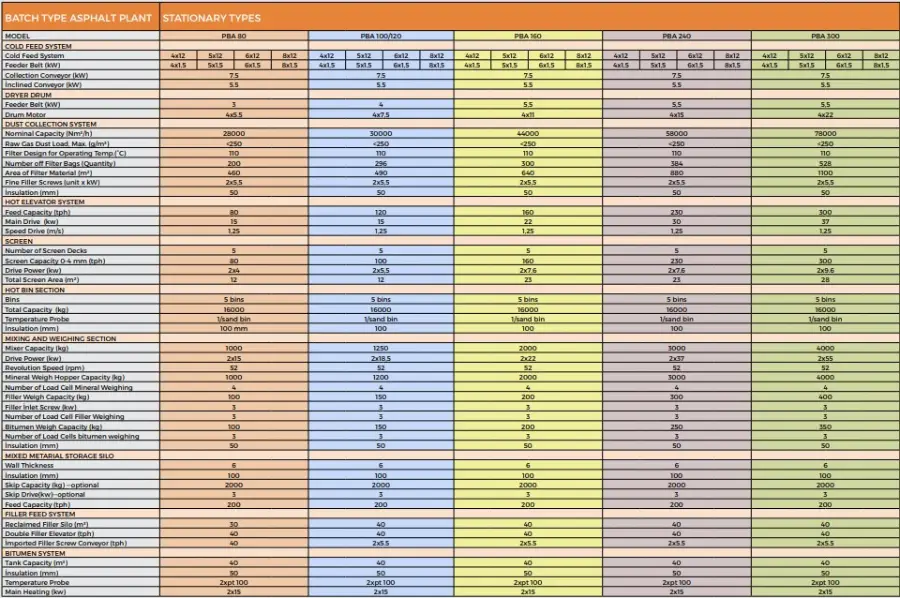

A number of essential parts make up the PBA 120-140 TPH Stationary Asphalt Plant which functions as a whole to produce high-grade asphalt. One essential part of the process is the asphalt mixer which creates the final asphalt mixture by combining heated aggregates and liquid asphalt binder. The asphalt products homogeneity and quality are guaranteed by the controlled environment in which this process is carried out. The decision between batch and drum mixers is based on operational preferences and the requirements of the particular project. The right amount of various-sized aggregates are added to the mixing process by aggregate feeders. The asphalt mixs quality and uniformity are preserved by these feeders which are managed by the central control system of the plant and guarantee exact aggregate proportions. While the filter system collects and eliminates dust and particulate matter to ensure environmental protection the drying drum prepares the aggregates by eliminating moisture and raising their temperature to the necessary level.

Bitumen Storage Tanks and Management System

Bitumen tanks are special storage units designed to heat and maintain the asphalt binder at a temperature suitable for mixing. The bitumen is kept liquid in these insulated tanks with heating elements inside allowing for precise and effective mixing with the heated aggregates. The brains of the plant the control system monitors and synchronizes every step of the production process guaranteeing accurate measurement and mixing managing the drying and heating processes and controlling the flow of production as a whole. The PBA 120–140 TPH Stationary Asphalt Plant assembly process starts with assembling the base and structural supports of the plant installing the aggregate feeders and drying drum adding the bitumen tanks and filter system and configuring the control system for smooth and effective operation. By following a methodical and thorough assembly procedure the plant is prepared to produce high-quality asphalt quickly and consistently.

What Makes Polygonmach Unique?

Polygonmach sets itself apart from rivals by emphasizing cutting-edge research and development and consistently coming up with new ideas to advance the technology used in asphalt production. By staying at the forefront of industry standards their plants are guaranteed to remain innovative. To ensure that customers are properly prepared to operate the PBA 120-140 TPH Stationary Asphalt Plant effectively Polygonmach also offers thorough training and support. This support ensures smooth operations for the duration of the plants life and includes maintenance troubleshooting and spare part availability. Leaders in the industry also favor Polygonmach because of its commitment to affordability and sustainability. As the market for sustainable building solutions continues to grow the companys plants are built to minimize their negative effects on the environment while maximizing quality and productivity. Clients that choose Polygonmach are investing in a time when every construction project will seamlessly incorporate sustainability efficiency and quality.

You can get a price by filling out the form